- Lactic acid – strong acid, weak spoilage inhibitor, fermented by bacteria in the rumen;

- Acetic acid – weak acid, good spoilage inhibitor, not fermented in the rumen;

- Ethanol – neutral, poor spoilage inhibitor, partially fermented in the rumen;

- CO2 (carbon dioxide – lost dry matter.

So the type of inoculant that should be used depends partially on the goal. If you want to preserve crop quality as close as possible to that of the crop at ensiling, use an inoculant that maximizes lactic acid production, a homofermenter. If you want silage that doesn’t heat, use an inoculant that produces acetic acid, which is the heterofermenter, L. buchneri.

Studies with homofermenters

A review of published studies by Muck and Kung back in 1997 resulted in data that are still useful today in showing the effects of adding homofermentative inoculants to silage. Regarding pH, it was lowered on average, but not all of the time; and it lowered the pH more often in hay crops versus whole grain silages. The percentage of trials in which the pH dropped was: alfalfa silage, 58 percent; grass silage, 63 percent; corn silage, 43 percent; and small grain silage, 31 percent.

In terms of dry matter recovery, it was improved in 38 percent of the trials. In the trials that showed an improvement in dry matter recovery, it improved by an average of 6 percent. When all trials were averaged, the improvement in dry matter recovery was 2-3 percent.

Regarding animal improvement, 27 percent of trials showed an improvement in feed intake; 52 percent showed an improvement in weight gain; and 46 percent showed an improvement in milk production. In the trials that showed improvement, the increases in feed intake, weight gain, and milk production were typically in the range of 3 to 5 percent.

Finally, when bunk life/aerobic stability were measured, there was an improvement in about 28 percent of the trials and a reduction in 31 percent of the trials; changes were generally positive in hay crop silages and negative in corn and small grain silages. In most cases, the effects, whether positive or negative, were small.

Studies with L. buchneri

Unfortunately in warm weather, bunk life is often an issue with corn and small grain silages. Because of the failure of homofermentative inoculants to increase aerobic stability in these silages, scientists began to look for inoculant species that could help keep silages from heating when exposed to air. One recent solution has been the heterofermentative species L. buchneri, which produces acetic acid both from sugar and lactic acid. Laboratory studies with L. buchneri have shown that it fairly consistently raises acetic acid concentration and results in a silage with a slightly higher pH. Because acetic acid inhibits yeasts and molds, the L. buchneri-treated silages have been more aerobically stable than untreated silage.

In terms of dry matter losses, silages treated with L. buchneri have been intermediate between untreated silage and silage treated with homofermentative inoculants. This is not surprising because CO2 gas is made and lost while producing acetic acid. Typically there is a 1-2 percent improvement in dry matter recovery over untreated silage.

In lactation trials with L. buchneri-treated silage, bunk life/aerobic stability increased consistently. Acetic acid also increased consistently – greater than 5 percent dry matter in several cases. However, there has been no effect on dry matter intake by the cows; and there has been little or no effect on milk production in most cases.

Studies combining homofermenters and L. buchneri

When combining the two types of silage inoculants, ideally we’d expect to get the best of both worlds – good fermentation, except for elevated acetic acid; the dry matter recovery and animal performance of a standard inoculant; and the bunk life/aerobic stability of L. buchneri. What’s the reality? Really, it’s too soon to make a conclusion based on published research. Several small-scale studies have been published. In these, it appears that combinations behaved more like the L. buchneri treatment than the homofermentative bacteria treatment in terms of aerobic stability, fermentation products, and pH. Right now we are waiting for enough animal trials to be reported to know what the cows have to say.

Harvest conditions when inoculants appear to be most useful

While some forage producers use inoculants nearly all of the time – an insurance policy, others strive to use it when they suspect it will be most useful – an educated guess. In the studies outlined earlier in this article, inoculants were used no matter what the harvest condition, so results could be lower than if a forage producer used the ‘educated guess’ approach of when to use inoculants.

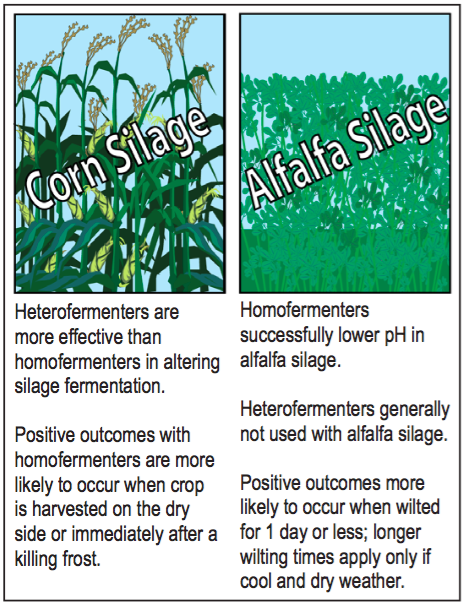

Research points to the following conditions when positive outcomes are more likely to occur when homofermentative inoculants are used:

- In hay crop silage – wilting times of 1 day or less; longer wilting times only if cool and dry.

- In corn silage – harvested on the dry side; immediately after a killing frost.

The L. buchneri inoculants (heterofermentative) appear to work more consistently across a wide range of conditions. However, there is much less published research on these inoculants from which we can draw strong conclusions.

Wet or dry Inoculants?

People often ask if wet inoculants or dry inoculants work better than the other. There appears to be no research that has specifically studied this issue. However, there is some anecdotal and common sense advice.

First and foremost, these products work only if the bacteria are alive when they’re put on the crop! Consequently, store them properly – generally in a cool and dry place. This is easier with inoculants applied wet because the packages are small and can be kept in a refrigerator until you need them. With the wet products, don’t use chlorinated water to dilute inoculants unless the chlorine level is less than 1 ppm or unless the inoculant contains chemicals to take care of the chlorine. Chlorine can’t discriminate between the bad bacteria it is meant to kill and the good lactic acid bacteria in your inoculant.

Also remember that these bacteria cannot move around on their own; they depend on the forage producer to spread them uniformly across the crop. This is often easier with the wet products that can be sprayed onto the crop at the chopper. However, there has been some recent concern from research in Delaware that dark colored tanks may get hot enough in the summer sun to reduce the numbers of live bacteria in the inoculant. So you should choose a wet or dry product based on how well you can keep the product alive both before and while applying, and how well you can get it mixed with the crop.

Summary

Standard homofermentative inoculants are the best route to improve DM recovery and animal performance. They’re a good fit for hay crop silages. They are less likely to be successful on corn silage where it’s harder to get consistent improvements, and there may be bunk life issues when they do work.

If a forage producer is adding inoculants because of bunk life/aerobic stability problems, he/she should first ask if the problem is due to a management issue that can be solved without an additive – such as getting a higher silage density or sealing the silo better or feeding out at a faster rate. If not, L. buchneri looks like a good alternative to propionic acid or anhydrous ammonia. It’s safer to handle, is cost competitive, and has similar effects on dry matter recovery and animal performance. L. buchneri is effective 80 to 90 percent of the time on corn silage. However, the bacterium is a slow grower that takes 45 to 60 days of storage time before having much effect. Consequently, it’s not an answer to heating problems with immature silage.

Good management: The most effective way to reduce dry matter and energy losses in ensiled forages

We don’t always see forage losses, but they can accumulate in a hurry. From the field to the cow’s mouth, as much as 60 percent of forage dry matter can be lost on farms. However, with good forage management, this loss can be reduced to as little as 15 percent.

The loss in dry matter does not occur equally across the board; the easily available carbohydrates, such as energy-rich sugars, disappear in greater proportions than the fiber or protein. Therefore, when dry matter losses are great, you not only have less forage to feed, but the silage that remains is of poorer quality.

Inoculants are a tool to reduce dry matter losses, typically by 2-3 percentage units. So they have a role in reducing losses. However, they have their biggest effect on losses when used together with good silage management practices.

Source:uwex.edu