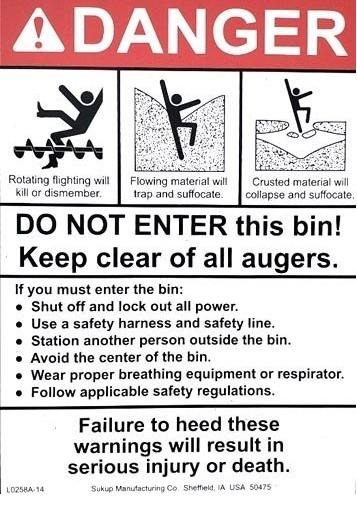

- Ensure all warning labels are present and visible.

- Use a lifeline and full-body harness system and have an observer on the outside of the bin.

- Lockout/Tagout all power sources before entry.

- Never enter a bin or transport vehicle while unloading equipment is active.

- Never work below grain stuck to bin walls.

- Do not work around grain alone.

Grain Augers

An auger is an implement with helical flighting driven by various power sources to rotate the flighting around a center shaft and carry material from one end of the auger to the other. Auger conveyors are used throughout the grain production process. When grain is harvested, an auger transports it from the harvester to the truck for transporting. Other augers transport the grain from trucks into the grain bins where it will be dried and stored. Occasionally, during the drying process, grain can be moved between bins which is usually done by an electric auger. After the grain is dried, augers are also responsible for transporting it from the bins back to the trucks. Depending on the application and volume of grain that needs conveyed, multiple auger configurations or sizes may be used. As useful and helpful as this equipment can be, it also presents significant hazards if not used properly.

Entanglement

Entanglements are severely traumatic life threatening injuries that often result in broken bones, loss of limb, or even death. Properly guarded augers and Power Take Offs (PTOs) can be the difference between a close call and a fatality. Ensure that all shields and guards are securely fastened in place and in good condition. When working around equipment, following these safe practices:

- Guards should be free of holes, dents, or deformations which can decrease effectiveness.

- Keeps hands, feet, hair, and clothing away from moving parts of machinery.

- Avoid wearing loose clothing and jewelry.

- Lockout /Tagout all equipment and power sources before performing service.

- Shutdown the equipment prior to doing any type of maintenance.

Additional Considerations

When performing tasks of any kind, especially around grain, it is important to establish safe working areas. Work areas should only be entered by authorized and trained personnel with proper Personal Protective Equipment (PPE). During times of operation, it is helpful to have barriers and signage in place to deter others from entering without permission. Furthermore, these areas should be well maintained to minimize the likelihood of an incident occurring. Ways to create a safe work zone include the following:

- Train workers on proper PPE for the task such as hand, eye, ear, and foot protection.

- Use barriers and signage to deter unauthorized visitors.

- Have a secure area for children and do not allow them to play in or around grain.

- Keep area clear of slip, trip, and fall hazards.

- Ensure equipment is working properly and all safety devices and guards are in place.

- Train operators on emergency shut-down procedures.

- Keep an emergency contact list in an easily accessed location.

Grain harvesting and handling can present many hazards and challenges for farm owners and employees. By promoting safety and ensuring equipment is well maintained we can complete tasks more efficiently and decrease the chance of an incident occurring.

Source : psu.edu