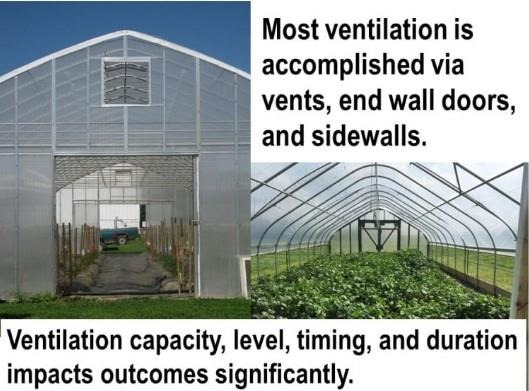

Crop yield and quality can be maximized through properly manipulating or managing environmental conditions inside the high tunnel (e.g., light, temperature, relative humidity, and wind in addition to soil moisture, fertility, and other key variables). Temperature, relative humidity, and air movement inside the high tunnel follow conditions outside it and the position (open to closed) of the end-walls, sidewalls, and vents, which are set by the grower. Research underway in Wooster and on the farms of grower-cooperators is designed to minimize the guesswork associated with knowing just what the ventilation status of a high tunnel should be at any one time to achieve the desired cropping outcomes.

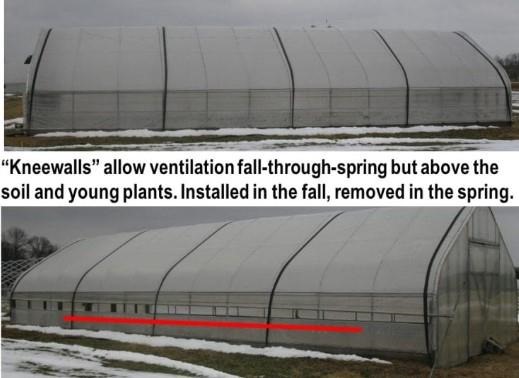

One study involves testing the impacts of “kneewalls,” which are sections of plastic installed behind approximately two-thirds of each sidewall for the fall through spring period. Most high tunnel sidewalls roll up to open. When ventilating fall through spring (e.g., to reduce temperature and/or relative humidity and/or increase carbon dioxide levels), opening standard sidewalls can expose crops or seedlings directly to cold air or wind and lower soil temperature, which is also undesirable. We suspect these problems can be mitigated by using kneewalls. We have experimented with them informally on a limited basis for four years and have been excited by our observations. We will soon begin rigorous, comprehensive assessments of the effects of kneewalls on crops and soils.