Production-quality Case IH tillage tools equipped with AFS Soil Command™ technology hit the fields for fall 2019 and spring 2020 season of use, and producers are sharing their experiences using this equipment on their operations. AFS Soil Command agronomically optimizes soil conditions through measuring, monitoring and controlling tillage tools. This advanced technology adds precision to soil management.

“Most operators don’t touch the settings on their tillage machines, but as this mentality changes with the new technology available today, producers are learning the importance of agronomically correct settings,” said Chris Lursen, Case IH tillage marketing manager. “We’re consistently hearing two different themes of feedback from producers: one being the ability to have an unskilled operator behind the wheel and know work is being done correctly, and the other being the agronomic advantages of a correctly set machine.”

Case IH AFS Soil Command™ technology agronomically optimizes soil conditions through measuring, monitoring and controlling tillage tools.

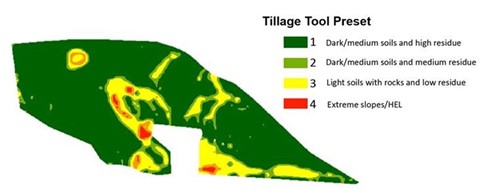

AFS Soil Command provides a data-driven approach to tillage. When planting, producers consider every seed in the ground — similarly, AFS Soil Command helps producers monitor and optimize soil conditions down to the square inch for tillage. Producers no longer have to “farm on the average” — use the same equipment and tillage settings through entire fields despite changing ground conditions. In-cab control allows each area of a field to be treated differently, and as-tilled mapping records all key tillage tool adjustments in real time.

Simple user interface empowers unskilled operators

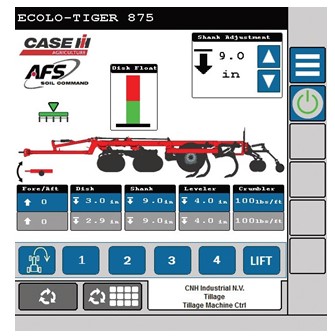

The AFS Pro 700 display and user-friendly interface make it easy for operators of any skill level to do agronomically correct tillage. With AFS Soil Command, the operator can optimize tillage tool performance through one-touch, in-cab adjustments and tillage tool performance.

“Having that capability where it's set and you can put some less skilled operators in the cab is a real advantage,” said Scott Johnson, who farms corn and soybeans in Wells, MN. “In the future, it will help us be more hands on or hands off in the areas that we need to be.”

Intuitive coordinated control

AFS Soil Command gives producers the capability to precisely control the entire tillage tool, not just depth, as field conditions change so the machine is always operating at peak agronomic performance. When an operator adjusts the depth, all other functions of the machine automatically adjust with main shank and disk depth adjustments. Operators can also record preferred settings as “groups” and use presets to return to a given set of adjustments for specific field conditions and easily return to preferred settings after headland turns, delivering proven performance and repeatable results. Adjustments made from the cab include shank and disk depth control, fore/aft leveling, and crumbler downforce on all Case IH tillage tools.

“A lot of times, our soil conditions vary across the field, so it’s ideal to be able to make adjustments on the go, from the cab,” said Al Klinkner, who farms in Lake Crystal, MN. “The presets are easy to use, because when you make one adjustment, it’s important to change all the settings to make your equipment do the job you want it to do. You can’t just pick up the front end — you need to adjust all the settings on your tillage tool.”

Case IH AFS Soil Command™ technology gives producers the capability to precisely control the entire tillage tool, not just depth, as field conditions change so the machine is always operating at peak agronomic performance.

Changing mindsets around tillage

The seedbed is the foundation of proper crop development — where the benefits of nutrients, proper germination, root stand potential and moisture level are seen. However, this important component lies hidden below the surface and is often overlooked, hindering crop stand and yield potential. Poor seedbed conditions often contribute to planting obstacles that could have been prevented during tillage. AFS Soil Command is designed to optimize seedbed conditions and maximize every inch of the field.

“In a good year, most people don’t think twice about what’s happening below the soil. In a challenging year like this with wet spring and fall compaction on the horizon, producers are taking a closer look and realizing there’s room for improvement,” said Lursen. “That’s where AFS Soil Command comes in — producers no longer have to ‘farm on the average,’ and when you pair technology with agronomically designed machines, you’re able to make the small changes and adjustments that yield results year after year.”

Case IH AFS Soil Command™ is currently available on Case IH Ecolo-Tiger 875® disk ripper, Tiger-Mate 255® field cultivator, True-Tandem™ 345/375 disk harrows and True-Tandem 335VT/Barracuda vertical tillage tools.

Effectively manage soil conditions with as-tilled mapping capabilities

AFS Soil Command is designed to identify problem areas across the field and give operators the knowledge and tools to fix them. As-tilled mapping technology now records all depth settings and crumbler pressure and where they were used at one-second intervals, helping to map out potential problem areas, which can be used for future adjustments in-field for a healthier seedbed and seedbed floor.

Tillage tool Preset map based on field slope and combine yield data.

AFS Soil Command is currently available on Case IH Ecolo-Tiger 875® disk ripper, Tiger-Mate 255® field cultivator, True-Tandem™ 345/375 disk harrows and True-Tandem 335VT/Barracuda vertical tillage tools.