While growers are encouraged to find all avenues possible to clean or market their corn, with elevated ear moulds in the 2018 Ontario corn crop, there may be fields with DON levels that render the crop unmarketable. These fields will require destruction in preparation for the 2019 crop season. Destroying a corn crop at harvest will present challenges for 2019, and research investigating destruction strategies at harvest time is limited.

Destroying Standing Crop

If the corn crop is still in field and there is a high confidence DON levels throughout the entire field are too high for marketing, or the field has been released by crop insurance and must be destroyed, there are a few considerations for destruction.

Grain Removal or Destruction

Volunteer corn management will be a key concern when destroying a corn crop at harvest time. A 200 bu/ac corn crop may produce around 400 kernels per square foot. One approach may be to remove grain from the field entirely or destroy kernel viability in-field:

Combine Harvest – Combining can remove grain entirely from the field. This is beneficial from a volunteer corn perspective, but harvest operations can be costly and still presents the challenge of disposing of large volumes of unmarketable grain (see “Disposing Unmarketable Grain Corn”). There has been some consideration of spreading and leaving kernels on the soil surface (avoiding tillage which may bury or protect kernels) to promote germination or rot, though practical experience with this method is limited.

Forage Harvester – Forage harvesting provides the advantage of simultaneously harvesting and destroying kernels in-field. While an additional cost, custom forage harvester costs for grain destruction may be comparable to custom combining, though local custom forage harvesters may not be an option for all growers. Combine heads would be preferred so only ear material is passed through forage harvesters (like earlage production) but require adapter kits for attachment. Kernel destruction is the goal, so kernel processors must be installed. Spout customization (deflector plate, fins etc.) is recommended to spread processed material across the full cutting width of the harvester. Assuming sufficient grain damage is incurred, removing recutter screens and operating cutterhead at maximum length of cut can increase efficiency. Where silage heads are used, the same settings are recommended while operating head as high as possible while still collecting ears. This will be processing more material, so will not be as efficient as an ear picking head.

Grain Incorporation and Management

Volunteer corn may still be manageable in 2019 without grain removal. When destroying the corn crop with tillage, it is essential to know a more intensive volunteer corn weed control program will be required next spring.

No or Reduced Tillage – Under a no or reduced tillage scenario, when a light disking or vertical tillage is used to knock down the crop and provide some cob to soil contact, good results have been reported when paired with proper volunteer corn management. This is expected to promote grain rot and more uniform germination of volunteer corn. This strategy will require soil conditions suitable for these tillage methods. Given the current wet soil conditions and lateness of the growing season, this may not be an option until spring 2019 for many growers. Chisel plowing is not expected to provide as good of soil contact or mixing.

Conventional Tillage – Reduced tillage is promoted for soil conservation, but for growers under conventional tillage practices, moldboard plowing may be the preferred tool for mixing cobs in soil to promote decomposition while also burying a portion of cobs to a depth where emergence is unlikely. Plowing is also a more suitable tillage option for late fall soil conditions. Plowing standing corn may not bury cobs, it is recommended to knock the crop to the soil surface (raised tillage implement, drag pole, mow etc.) prior to ensure burying.

Volunteer Corn Herbicide Management in 2019

Soybeans – In situations where the previous year’s corn crop has been destroyed, volunteers will be at much higher densities and control will be challenged by a prolonged germination period. A two pass early (soybean V1) and late (soybean V5) application program that targets volunteer plants prior to the 6 leaf stage of growth will be critical for controlling high densities of early and late emerging volunteer plants.

There is experience through planting soybeans after studies where corn was harvested in the spring with high ear losses (100-150 bu/ac). A pass with a vertical tillage tool was made prior to soybean planting to encourage early and “uniform” corn germination. An early pass (early soybean V1) with a graminicide was critical to control the first flush of corn, followed by a late (soybean V5) application to control later emergers or escapes from the first pass. The higher rates of graminicides should be used in each pass.

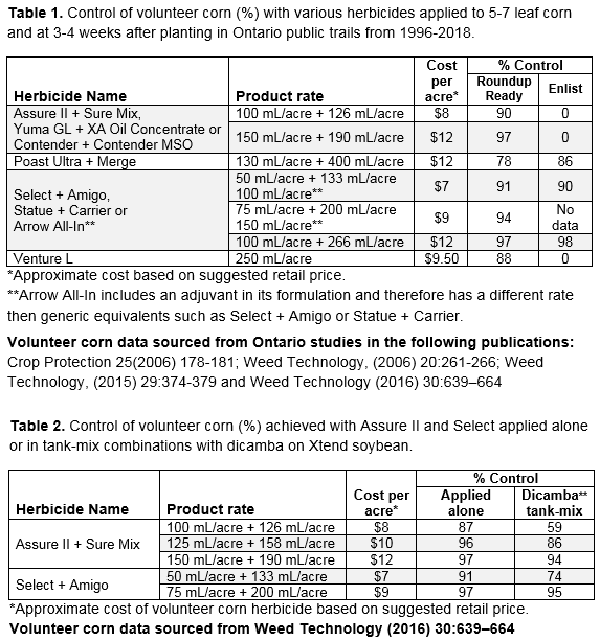

Volunteer plants from Roundup Ready and Liberty Link corn hybrids are easily controlled by a number of herbicides provided they are applied prior to the 6 leaf stage (Table 1). However, volunteer plants from Enlist corn hybrids are not controlled by Assure II (quizalofop-p-ethyl) and Venture L (fluazifop-p-butyl). Therefore herbicides that contain the active ingredient “clethodim” (i.e. Select, Statue or Arrow All-In) should be used instead (Table 1).

Xtend soybeans – Antagonism can occur when tank-mixing volunteer corn herbicides with dicamba (i.e. Engenia, FeXapan or Xtendimax) thereby reducing the level of volunteer corn control. Rates of the volunteer corn herbicide should be increased to overcome this antagonism when tank-mixing (Table 2).

Corn – Corn should not be grown in 2019 in fields where corn will be destroyed this fall, as there are generally no volunteer corn control options in corn. Exceptions do exist. The first exception would be when a non-Liberty-Link hybrid was grown in 2018 and a Liberty-Link hybrid will be grown in 2019. In this scenario Liberty 200SN could be used to manage the non-tolerant volunteers. The second exception would be when a non-Enlist hybrid was grown in 2018 and an Enlist hybrid will be grown in 2019. In this scenario, Assure II could be used to manage the non-resistant volunteers. Consult with your seed provider and Certified Crop Adviser (CCA) to verify if these exceptions apply.

Disposing Unmarketable Grain Corn

If unmarketable corn has been removed from the field (rejected loads, corn removed to prevent volunteer corn) there are a variety of options for disposal, though feasibility varies significantly.

If volumes are large and viable grain is not to be returned to the field, one of the more feasible options may be to grind corn (tub grinder, roller mill etc.) and return it back to the field. This will have equipment expenses for grinding and spreading, but will benefit from organic matter, nutrient value of the returned corn and significantly reduced volunteer corn.

Stockpiling or burying unmarketable corn would be options, but would take up considerable space or require significant effort given corn volumes.

Corn infected with DON can potentially be used as a feedstock for anaerobic biodigesters. However, only a limited number of digesters capable of handling grain corn exist in the province. Grain corn will likely require grinding and ensiling prior to feeding a digester, as whole kernels will simply sink to the bottom of the digester.

Composting grain may be an option, but requires significant water addition and active management.

Landfilling contaminated grain is costly. Above transportation, costs in excess of $100/tonne can be expected from municipal landfills.

Burning compromised grain to produce heat is a possible alternative. Corn as a heating fuel is currently 3 times less expensive than propane or heating oil. However, specialised furnaces or boilers are needed, and would only be feasible if the heating system already exists. Impacts of DON release in combustion exhaust would also need to be investigated.

Other Considerations

Grain corn contains significant levels of fertility. Crop removal data in Ontario from NMAN software suggests 83-42-29 lb of N-P-K for every 100 bu. While grain corn is not expected to decompose in time to provide significant fertility credits for the following crop, it will still contribute to soil fertility maintenance. Using NMAN removal values, the P and K from a 180 bu/ac corn crop would provide 76 lb/ac of P2O5 and 52 lb/ac of K2O, or roughly $70/ac† of fertilizer value for soil fertility. This would be an added benefit of any strategy returning grain material to the field.

† Assumes an average price for monoammonium phosphate (MAP, 11-52-0) of $740/tonne and muriate of potash (0-0-60) of $485/tonne (Ontario Farm Input Monitoring Project, October, 2018)

Authors would like to thank the following for their contributions towards this article: Dr. Tony Vyn, Purdue University; Dr. Dave Hooker, University of Guelph, Ridgetown Campus; Greg Stewart, Maizex Seeds; Paul Foran, Dow AgroSciences; Hauke and Sonke Claussen, Claussen Farms Custom Farming Inc.

Click here to see more...