By Sjoerd Willem Duiker

Crop residue is an important resource to optimize soil function. In a South Dakota study, the impact of leaving or removing corn residue in a no-till corn-soybean rotation was determined. After 15 years, soil organic carbon in the top 2 inches was 22% greater and total nitrogen was 17% higher where residue was retained. In an Ohio study, years of corn residue removal in continuous no-till corn reduced the total nitrogen pool 730 lbs/A. According to Michigan State, nitrogen content of corn stover is 22 lbs/ton and potassium content is 32 lbs/ton. A 150 bu/A corn crop produces about 3.5 T/A of crop residue, so would contain 77 lbs/A N and 112 lbs/A potash, contributing significantly to soil fertility. In the South Dakota study, penetration resistance was 24% lower in the top 2 inches, and bulk density was often lower to 6 inches depth where residue was retained. Further, water holding capacity and infiltration rate were greater where crop residue was retained. In one year, infiltration rate was 67% higher where residue was retained (4.3 vs 2.3 inches/hr), while in the other year it was 23% greater. Soil water storage in the soil profile was in general greater where residue was retained. These studies show the important value of retaining crop residue, especially in no-till, for soil fertility, water infiltration and retention, and soil porosity and tilth. But to benefit from residue it is important to spread it evenly over the soil surface. With today’s increasing harvest width, residue can easily be deposited in distinct swaths, separated by zones with very little residue. This would reduce the benefits of residue for soil function.

Unevenly distributed residue behind the combine can cause problems such as:

- Hairpinning and variable seed depth. Windrows and piles of residue will cause unsatisfactory planter or drill performance. The problem is worst when planting cover crops immediately after harvest but will still be present next year at corn or soybean planting time. The seed slot openers cannot cut through excessive residue, and seeds are not planted in the soil. Row cleaners can help but not completely eliminate this problem next season.

- Non-uniform soil temperature and moisture conditions. The soil under heavy residue will be several degrees cooler and will be more moist than bare soil causing differences in crop emergence.

- Soil fertility uneven. Nutrients in crop residue will be concentrated under the bands of high residue. Most immediate effects could be noticed for potassium, although total nitrogen pool will also be affected over the long run.

- Increased pest pressure. Pests such as slugs and rodents reside in residue piles.

- Weed control problems. Weed seeds and grain lost through the combine will be concentrated in the residue patches. Concentrated weeds and volunteer crop plants are difficult to control. Herbicide effectiveness will be compromised because the herbicides don’t reach the soil.

Right now is a good time to take a look at residue spreading behind your combine. There are things that can be done at the front and back of the combine to improve residue distribution. You should limit the amount of residue that is taken into the combine and distribute whatever comes out at the back evenly over the entire harvest width.

It is most beneficial if residue never enters the combine because in that case, it stays where it’s at and you don’t have to worry about spreading it. The combine head can be set up to limit crop residue intake, also improving harvest efficiency and reducing fuel consumption. Raising the head is one option to avoid taking in too much residue. Corn heads should strip the cobs off the plant, leaving most of the corn plant before it enters the combine. There are trash reduction kits available that allow you to modify your head to accomplish this objective better. Besides helping with residue distribution, these kits also help to improve combine performance and allow for faster harvesting speed. In addition, these kits may include crushing knife rolls to crush corn stalks to speed up decomposition. There are also chopping corn heads that chop up stalks for faster decomposition. There are a couple of manufacturers making these. They come at a price and require extra power – estimated at 1.5-7 hp per row. They leave the residue in a uniform blanket on the soil. Personally, I prefer to leave as much of the stalks standing as possible and limit the amount of residue that is loose on the soil surface because it can easily be blown around by wind or carried away with runoff.

At the back of the combine, chaff, stalks, leaves, and cobs or empty pods need to be distributed over the entire width of the combine head. Larger heads will necessitate more aggressive residue spreading. Some of today’s spreaders are capable of spreading residue up to 45 feet wide. To spread residue, the older model combines have bat spreaders, while new combines all come with rotary spreaders. However, pay special attention to chaff. My experience is that many combines lack chaff spreading capability, and this fine material is dumped in a 3-4 ft width making a real dense mat. If your combine does not have a chaff spreader, I suggest you get an after-market model and mount it on the combine. It will make a big difference. If you have a batt spreader on your combine, make sure the batts are all the same length, and that their edges are not rounded. Replace the batts if they are worn. Deflection fins, if adjustable, and rotation speed of the batt spreader can be used to adjust for residue quantity, moisture content, and width of the harvesting platform. New combines come with rotary spreaders. Some of the new systems, like the New Holland Opti-Spread Plus System, have adjustable speed from the cab so you can adjust the width of distribution and can also adjust for cross-winds. On other models the tail board can be adjusted upwards or downwards, affecting width of throw. Fins in the tailboard can also be adjusted and different types of fins are available, affecting how far residue is thrown. Knives on rotary choppers need to be checked from time to time for wear and breakage and need to be replaced if needed. Make sure to follow manufacturer’s instructions when doing so. Case IH recommends changing knives of opposite pairs on the rotor to avoid the rotor from becoming unbalanced, for example. The issue of residue spreading is really important but seems to be often neglected by dealers so you may need to press them a little to get the help you need to make sure your combine does the best job it can for successful no-tilling.

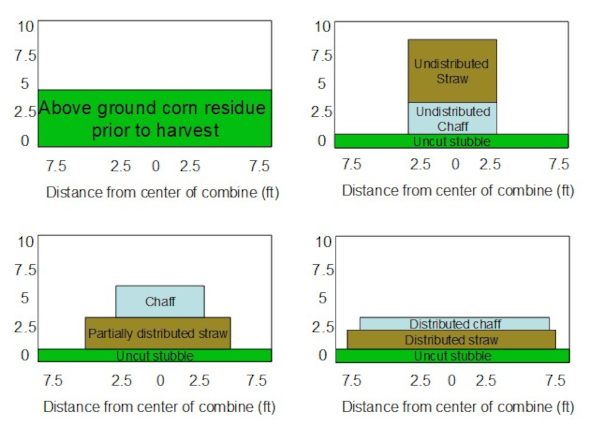

Figure 1. Clockwise from top left hand: crop residue distribution before harvest, after harvesting without residue spreader on the combine, with a poor residue distribution system, and with quality residue distribution.