Many grain farmers may have questions about storing and drying corn this year, with recent propane shortages and a lot of wet corn still in the field. Decisions for harvesting corn will vary from farm to farm based on local conditions and factors (corn moisture, distance to alternative dryers, crop standability). Some farmers may already have harvested wet grain and now are unable to dry it.

Wet corn can be safely stored for short periods of time, depending on the moisture level and temperature of the grain. This is a short term solution and is not recommended for very wet grain (e.g. above 25% moisture). The table below shows the estimated time, in days, corn can be stored at various temperatures and moisture levels before spoilage becomes significant.

This chart assumes the corn being stored is high-quality, with good test weight and free of significant damage, cracking or fines. The safe storage period for lower-quality corn (e.g. lighter test weight, high fines, significant number of damaged kernels) will be much shorter.

It is very important to understand that allowable storage time does not “reset” when corn is dried. For example, if corn is stored at 4 deg C and 24% moisture, it can be safely stored for approximately 56 days. If it is stored for 27 days, 50% of the storage time has elapsed. If the corn is then dried to 15% and stored at 4 deg C, the new storage time will be only 50% of that shown in the chart above.

Follow these steps to reduce the risk of wet corn spoiling while in storage:

- Measure the corn moisture before storage. Estimate the safe storage length at that moisture and at the coldest reasonable temperature give current weather conditions (see table 1 above).

- Ensure the corn is high quality and free from significant damage. Clean the corn if necessary to remove broken kernels, fines and foreign materials.

- Put the corn into a storage bin equipped with a full aeration floor and aeration fans of reasonable capacity (at least 1/2 CFM of fan airflow per bushel of grain in the bin is recommended). If fan capacity is small, increase the effective airflow per bushel by filling the bin less full (i.e. fewer bushels in the bin)

- If possible, use a storage bin with a grain temperature and moisture monitoring system installed.

- Keep track of the date the bin was filled.

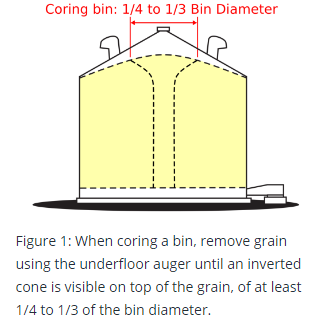

- Core the bin after filling to remove fines, which tend to collect in the centre as the bin is filled (see Figure 1)

- Level the bin after coring. This ensures consistent airflow through the grain mass for better aeration.

- As soon as the bin is cored and leveled, run the aeration fans to cool the grain down and minimize any hot spots. At 1/2 CFM airflow per bushel, cooling will take approximately 40 hours. Monitor the grain temperature at the top of the bin to check when cooling has completed (this grain will be the last to cool down).

- Run aeration fans at night when the coldest temperatures occur.

- Aerate bins at least 24 total hours each week, to maintain cold temperatures. Left alone, wet grain can begin to heat spontaneously which accelerates spoilage.

- Monitor grain weekly looking for hot spots, visual spoilage, off-odours and any other signs of spoilage. Use bin temperature and moisture monitoring systems if available.

- Remove the grain from storage once 60-70% of the allowable storage time has elapsed, and send it for drying or other uses. Once the corn has been dried, sufficient storage time will remain to store safely for a reasonable period. For lower quality corn, store no longer than 30-40% of the allowable storage time.

Storing wet corn for short periods can be done but requires close management. It can provide brief relief from a drying backlog but should be done carefully, and only once the risks are fully understood.