Deck plate settings

Setting deck plates in variable field conditions caused by poor stands in some areas can be challenging, hydraulic adjust deck plates help a lot but if they are not automatic adjust you will have to adjust them as conditions change throughout the field. Under normal conditions deck plates should be set to 1 ¼ inches in the front and 1/8 inch wider at the back, 1 3/8 inches. While this is a starting point, a better method is to use actual stalks of corn and set the deck plates 1/16 of an inch wider at the front than the third node width of a corn stalk. If you check the best and the worst corn in the field you should be able to get an idea of how to vary deck plates on the go, possibly make marks on the indicator gauge to know where you want to be in each area. The basic goal is to keep deck plates narrow enough that we avoid butt shelling and ears slipping between the plates into the stalk roll but still manage to be wide enough that most of the stalk and leaves get pulled though. When stalks are damp and tough, opening deck plates wider allows the stalk and husk to flow through better. If stalk lodging is present, increasing the deck plate taper (more open at the top) will decrease the fodder entering the combine but may increase butt shelling.

Stalk roll and gathering chain speed

The other major setting is matching gathering chain and stalk roll speed to combine ground speed, which can be a challenge if you cannot vary header speed from the combine cab. Since the threshing system works best when full, we often increase ground speed in lower yielding areas. However, if the gathering chains/stalk rolls speeds aren’t adjusted to match the change in ground speed, our header loss will increase. The rule of thumb is when ground speed is 4 mph gathering chains should be running at 55 rpm, with the ratio staying constant across all ground speeds. Headers should be ran slower in wet, green corn since the leaves do not strip off and provide cushion to the ear impacting the deck plates. Running heads slightly faster in dry corn allows more plant material to move down through the rolls and cushion the ears as leaves strip off. Chain lugs should be opposite each other. With variable field conditions, making sure your rubber ear savers are present and flexible will prevent whole ears from being lost. In high moisture corn around 30%, grain damage can be caused by the header auger running to much clearance to the auger trough or too tight. The initial setting for most headers is 1-1 ¾ inches between the auger and the trough at the tightest point.

Threshing

Increased fodder making it past the header leads to higher threshing loss. If fodder is present, double check the header settings.

Cob investigation to set rotor and concave

The first consideration in threshing settings is cob integrity, which is often compromised in stressed and high moisture corn. When setting concaves the goal is to not break cobs into more than 2 pieces crosswise and not break them length wise at all. The initial concave clearance on most machines is 3mm over cob diameter. Setting the concave clearance and rotor/cylinder speed is the first steep to a clean sample and maximum machine capacity. Cobs should be coming out the back of the machine intact but when you break them in half, there should be signs of compression. Rotor or cylinder speed should be set using your book and only increased if concave clearance is set properly and ears are still not threshed. Increasing rotor speed can increase threshing quality without breaking cobs better than tightening concave settings. In wet corn, damaged grain is more often caused by high rotor speed than narrow concave settings, often rotors need slowed down compared to book values.

Concave selection

When harvesting high moisture corn, technically anything over 22% according to most manufacturers, different concaves can help with threshing. Changing the large wire concaves to round bar, either straight or fish bone helps maintain cob integrity and grain quality in wet corn. Extremely wet corn, over 30% moisture, will need round bar concaves to maintain threshing grain quality. Damp fodder also does not get stuck on the round bar concaves as badly as large wire, reducing rotor loss. Another option if you are having issues with fodder plugging concaves is to remove every other wire, creating skip wire concaves. If using skip wire, usually keep large wire in position one. Moving rotor vanes to the slowest position possible will help decrease rotor loss. Wet corn can be damaged much more easily during threshing.

Cleaning shoe

The last settings are in the cleaning shoe: fan speed and sieve opening. In corn, especially wet corn, most if not all of the separation and cleaning should take place on the top sieve.

Sieve setting

For dry corn, the lower sieve should be closed a little tighter than the top sieve. In wet corn, many manufacturers recommend opening the bottom sieve all the way so that corn easily moves into the clean grain elevator and does not overload the tailings auger. A common starting opening is 5/8 inch, then open until the first cob appears in the grain tank and shut one notch.

Cleaning fan

Fan speed should be increased until all red chaff is gone from the grain tank then slowed down 30-50 rpms to keep grain from being blown out the back. Often fan speed settings are opposite of logic, increasing fan speed often decreases losses because chaff floats more allowing grain to fall through the sieves better.

Checking harvest loss and combine settings

When assessing combine settings there are four areas of loss to consider. The first is preharvest loss. Each dropped ear per 1/100th of an acre equals about 1 bushel per acre (1/100th of an acre equals 29 feet for 6 row headers or 21.8 feet for 8 row headers). The next source of loss is header loss, then threshing and sieve loss. When counting individual kernels, 2 kernels per square foot equally distributed equals 1 bushel per acre.

To determine which part of the combine to adjust, you need to calculate loss from each area.

Header loss

Stop the combine and back up the length of your combine

Count the number of kernels in front of the combine from center of row to center of row (for 30 in. rows count for 4 feet of row length, 10 square feet)

Each row of your header should be checked and recorded separately, since only one may be out of adjustment

Also check for additional ears that may have been lost by the header and not pre harvest, remember one ear per 1/100th of an acre equals a bushel.

Divide by 20 to get bushels per acre

Separator loss

Count the number of kernels behind the combine from center of row to center of row (for 30 in. rows count for 4 feet of row length, 10 square feet)

Each row of your header should be checked and recorded separately, since only one may be out of adjustment

Divide by 20 to get bushels per acre

Subtract each row individually from header loss to calculate separation loss

Threshing loss

Count the number of kernels on partially threshed cobs behind the combine from center of row to center of row (for 30 in. rows count for 4 feet of row length, 10 square feet)

Each row of your header should be checked and recorded separately, since only one may be out of adjustment

Divide by 20 to get bushels per acre

Subtract each row individually from header loss and separation loss to calculate

threshing loss

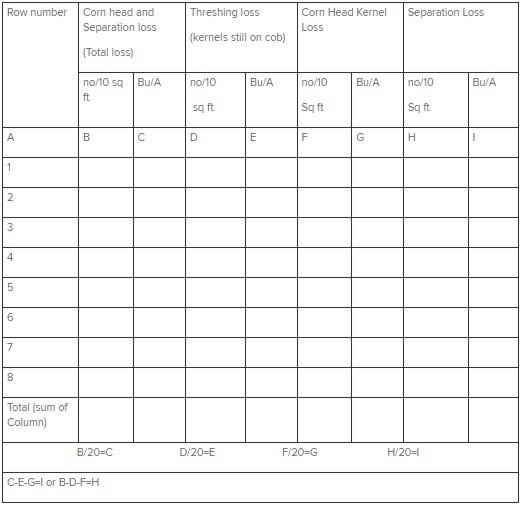

A study conducted in Iowa found the best set combines have a total loss, pre and post-harvest loss, of 1.5 bushel per acre. Use the table below to calculate losses, remember kernels per 10 sq ft divided buy 20 equal bushels per acre.

Setting Harvest Loss/Tattletale Monitors

Once your machine is set to expected harvest losses, adjust your loss monitors. Harvest lost monitors work by sensing grain impact on the sensors, grain size and sensitivity can be adjusted to calibrate these loss monitors. Larger grain hits more area on the sensor, increasing loss values. Larger, harder grain also hits with more force. Usually you adjust grain size and then sensitivity.

Taking the time to properly set your combine can help minimize harvest losses. With the challenging conditions so far this fall, this extra time may really pay off. Good luck with harvest!

Source : osu.edu