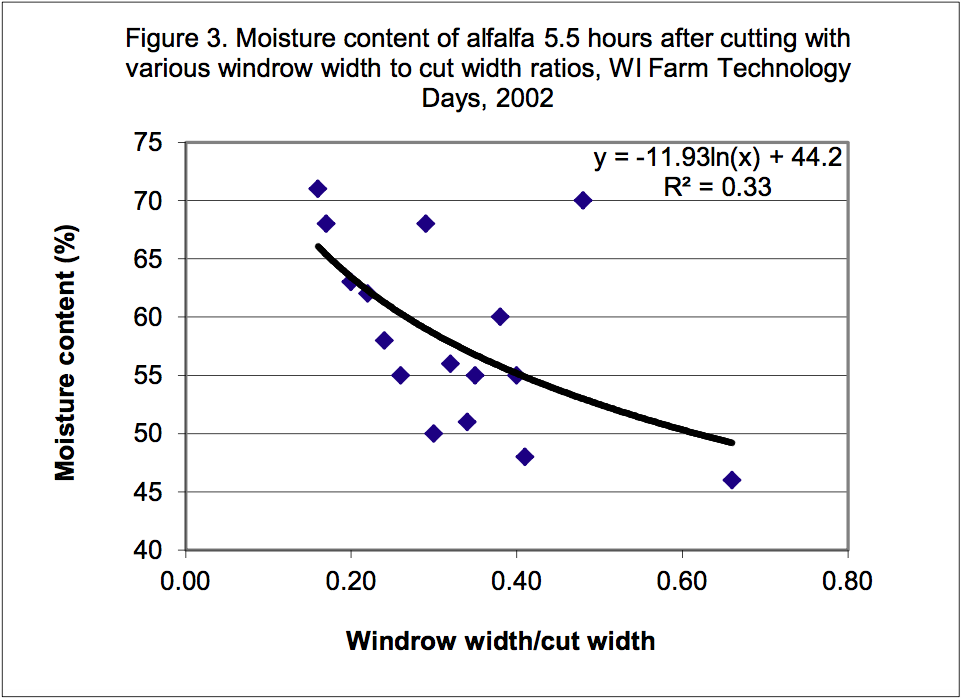

The importance of a wide swath is supported from drying measurements taken at the Wisconsin Farm Technology Days in 2002 (figure 3) where different mower-conditioners mowed and conditioned strips of alfalfa and put the cut forage in windrow widths of the operators choice. Moisture content of the alfalfa was measured 5.5 hours after mowing. Each point is a different machine that included sickle bar and disc mowers and conditioners with steel, rubber or combina- tion rollers. Across all mower types and designs, the most significant factor in drying rate was the width of the windrow.

In figure 3, note the one outlying point at 70% moisture content and a windrow width/cut width ratio of 0.48. This shows how much drying can be slowed by improper adjustment of the conditioner.

Many farmers have gradually gone to making windrows that are smaller percentages of the cut area as mowers have increased in size. Generally, the conditioner has stayed the same size as mower cutting bars have gotten bigger, resulting in narrower windrows. There is some variation among makes and models and growers should look for those machines that make the widest swath.

Does swath width influence forage quality?

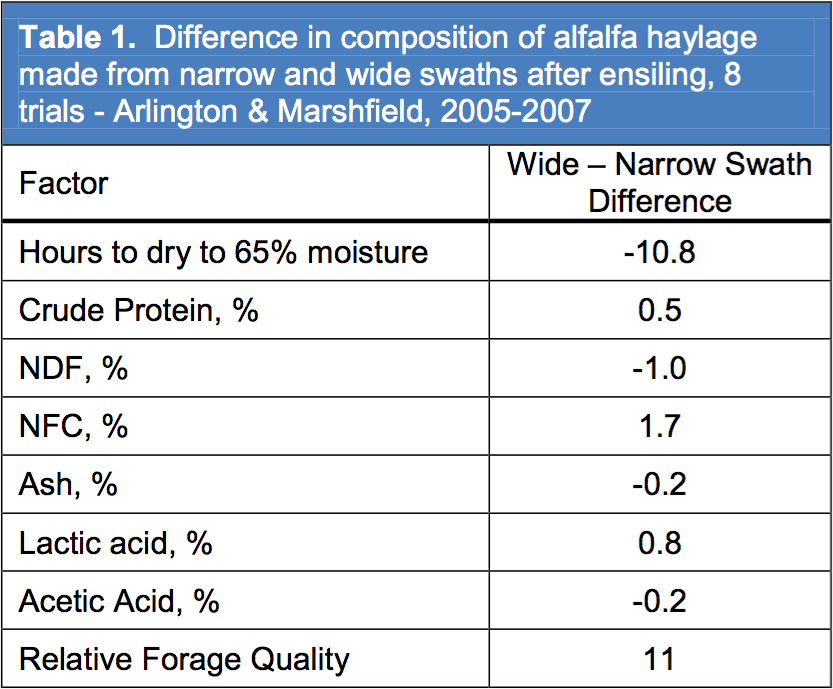

Putting alfalfa into wide swaths (72% of cut width) immediately after cutting often results in improved quality of alfalfa haylage compared to narrow windrows (25% of cut width) in studies at UW Arlington and Marshfield Research Stations in 2005 to 2007 (Table 1 ). Alfalfa was mowed with a discbine, conditioned, and haylage was sampled approximately two months after ensiling in tubes. The alfalfa from the wide swaths had 1.0% less NDF, and 1.7% more NFC. Haylage from the wide swath had more substrate for fermentation which resulted in more lactic and acetic acid. The higher acid content would indicate less rapid spoilage on feedout.

A wide swath requires that one or both tractor wheels drive over the swath. While this may not be desirable, it results in less loss than making a narrow windrow. The reduced drying of the wide swath with a driven-over portion is less than if a narrow windrow is made. Also, as table 1 shows, the ash content of haulage from wide swath alfalfa was actually less than from narrow windrows with no wheel track. Narrow windrows tend to settle to the ground causing soil to be included with the bottom of the windrow when it is picked up. Wide swaths tend to lay on top of the cut stubble staying off the ground. Driving on the swath can be minimized by driving one wheel on the area between swaths if swath covers less than the full cut width.

Grasses, especially if no stems are present, must be laid into a wide swath when cut. They generally must also be tedded about 24 hours after cutting and then raked into a windrow later. Grass forage, when put into a windrow at cutting, will settle together, dry very slowly and be difficult to loosen up to increase drying rates.

Recommendations

- Cut at the proper height – 2 to 4 inches for alfalfa and 3 to 4 inches for grass or legume/grass mixtures.

- Adjust conditioner properly. Roller conditioners are best for alfalfa due to reduced leaf loss. Either type, if properly adjusted (1 to 5% of leaves show some bruising), will cause drying at a similar rate.

- Lay hay in a wide swath covering 70% or more of the cut area to enhance rapid drying.

- Rake/merge ahead of chopping or at a moisture content that minimizes leaf loss for hay (40 to 60% moisture – often reached 24 hours after mowing).

Source:uwex.edu