By Lee Johnston, Mike Reese.et.al

Over the last couple years, WCROC researchers have been involved in a project entitled “Greening of Agriculture”. This project focuses on methods to reduce the use of fossil fuels in production agriculture. Many markets and food supply chains are encouraging food producers (farmers) to reduce their use of fossil fuels as a way to reduce the carbon footprint of current food production systems. Currently, as part of this project, we have research studies underway in the areas of agronomy, dairy production, and swine production. The overarching objective of these studies is to help farmers respond to market demands in a way that will reduce environmental impacts of and maintain the economic viability of their production systems.

The swine production portion of the Greening of Agriculture project has focused on cooling sows to improve performance during summer using solar-generated electricity. During summer in Minnesota, sows that are nursing their piglets often experience heat stress. High environmental temperatures in rooms that house sows and their litters cause sows to reduce feed intake which causes increased weight loss from sows and poor breeding performance of sows after pigs are weaned. Poor breeding performance compromises the biological and economic efficiency of a swine breeding operation and makes the carbon footprint of the operation less environmentally friendly. There are several approaches to help sows cope with heat stress but they are not entirely effective and many have specific drawbacks. So, the current project is designed to investigate a more effective cooling system.

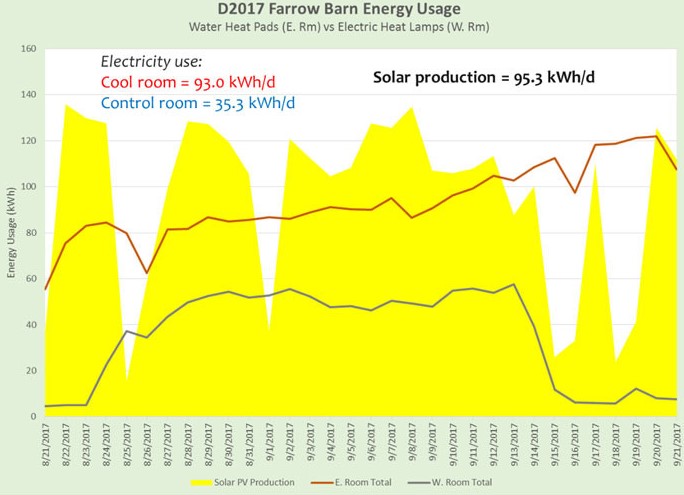

In the cooling system designed for this project, we installed a 20 kW solar photovoltaic array to power a chiller. The chiller circulates cool water (70 °F) under the metal floor that sows lie on providing a cooling effect in the same way a residential under-floor heating system can heat a home. The cooled water cools the floor and thus cools the sow as she lies on the floor. During hot periods of the day, sows typically spend much of their time lying. In addition to the cooled flooring, we supplied cooled water (55 °F) to the drinker that supplies drinking water to the sows. Our preliminary data collected on commercial swine farms suggests that drinking water for sows can range from 55 to 78 °F throughout the year. So, we expected that a consistent supply of cool drinking water would help keep sows comfortable. Our approach is to cool sows from the outside with the cooled flooring and from the inside with cooled water. A cool sow will eat more feed, and be more productive than a heat-stressed sow. For the experiment, we used two mirror-image, farrowing rooms each equipped with 16 farrowing stalls. The control room was identical to the cool room except that there was no cooling of floors or drinking water for sows. The study included 41 sows and litters in the control room and 43 sows and litters in the cooled room. Sows and litters were studied from entry to the farrowing rooms (about 5 days before farrowing) until pigs were weaned at about 21 days of age. Studies were conducted during the summer months so that room temperatures could be maintained above 75 °F. We measured sow and litter performance, sow comfort, and electricity use in each room.

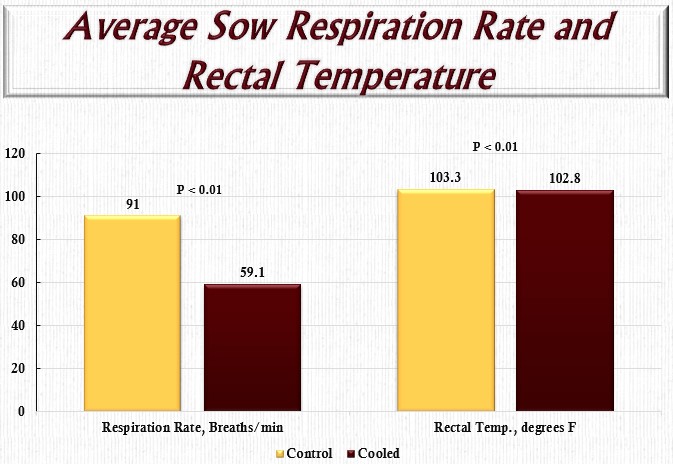

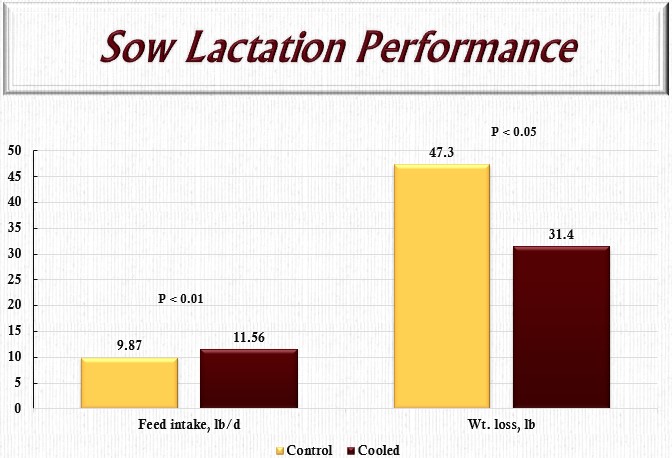

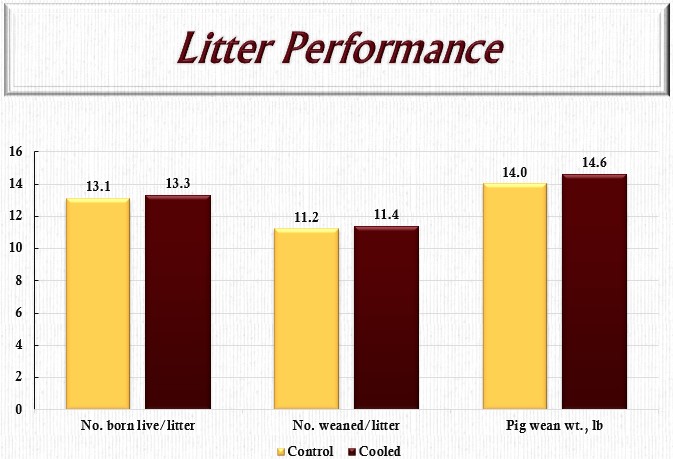

Results of our study indicated that we did improve the comfort of sows in the cooled room. Sows housed in the cooled room expressed a significantly lower respiration rate and rectal body temperature than sows in the control room (Figure 1). Respiration rate is a very sensitive measure of heat stress. So, our cooling system did make sows more comfortable during heat stress conditions. This improved sow comfort resulted in higher daily feed intake of sows and lower loss of body weight during lactation for cooled sows compared with sows in the control room (Figure 2). Unfortunately, this improved comfort and higher feed intake did not translate to better performance of suckling litters. Litter size born alive and weaned were not different between cooled and control rooms (Figure 3). Similarly, body weight of pigs at weaning was not statistically different between cooled and control rooms. Finally, use of electricity in the cooled room was at least 2.5 times higher in the cooled room compared with the control room (Figure 4). This high electricity use in the cooled room was due mainly to the power use by pumps that circulated cool water under sows and in drinkers and was consistent across all farrowing groups. In all farrowing groups, the solar array produced enough electricity to satisfy the electricity needs for the cooled room.

In conclusion, our cooling system was effective in cooling heat-stressed sows. However, this improved comfort of sows was not reflected in larger litters or heavier pigs at weaning. So, the cooling systems we studied provided little economic benefit to pig farmers.