By Michael Reese

This past fall, Minneapolis was again host to the NH3 Fuel Conference on November 1st and 2nd. Following the 14th annual conference, the West Central Research and Outreach Center (WCROC) hosted program leaders from the US Department of Energy ARPA-E REFUEL program (Washington DC), researchers from Siemens (Germany and UK), and IHI Corporation (Japan). The guests toured the Renewable Hydrogen and Ammonia Pilot Plant and discussed research efforts with the renewable energy team.

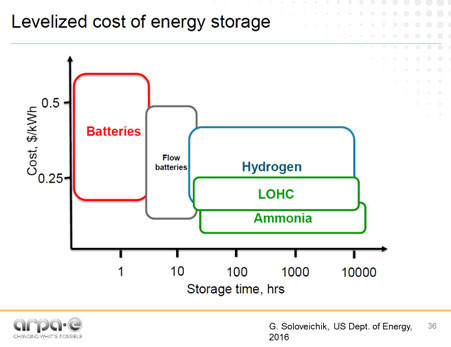

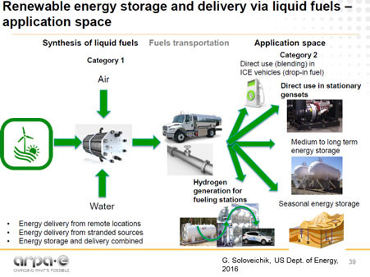

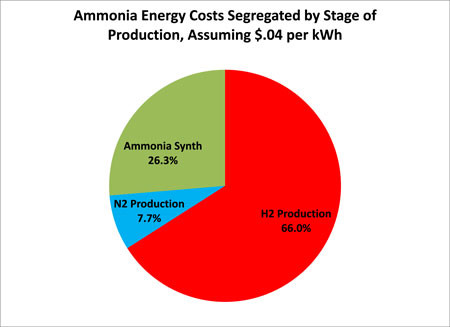

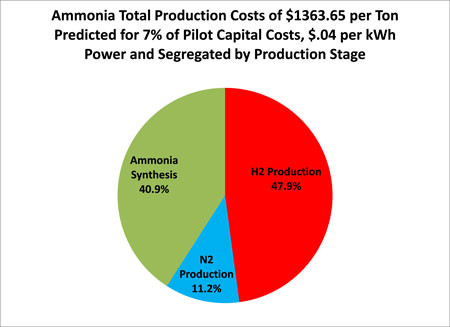

One of the inherent disadvantages to wind and solar electric generation systems is that the power production does not always match the electric load or demand. Finding methods to storage wind and solar PV for periods of higher demand is paramount to increased development of renewable electric generation. There are many options for storing power such as batteries, compressed air, hydrogen production, and pumped hydro. However, most of these options tend to be too expensive. As shown in Figure 1 and 2, using ammonia for energy storage appears to be more economical, and have the added advantage of long term storage, transportability, and market flexibility (eg. Use as nitrogen fertilizer).

Producing ammonia from wind and other renewable resources such as solar PV has gained considerable momentum buoyed, in part, by the $30 million ARPA-E REFUEL research program. The REFUEL program focuses on the production of ammonia from renewable sources and the utilization for electric generation and transportation fuel. Using ammonia as an energy storage and transport medium for renewable energy is also gaining interest around the world. Siemens has just completed a wind to ammonia pilot plant in the United Kingdom and has recently signed on to partner on a larger plant in the Netherlands. Since Japan is moving away from nuclear power due to the Fukushima disaster, efforts are underway to produce ammonia from solar PV. For example in Japan, the IHI Corporation is developing boilers that combust ammonia. Others in Japan are interested in using ammonia for vehicle fuel and electric generation. Yara, one of the world’s largest ammonia producers, is developing a production facility in Australia using solar PV. The ammonia product is expected to be exported to Japan to help meet the country’s energy needs.

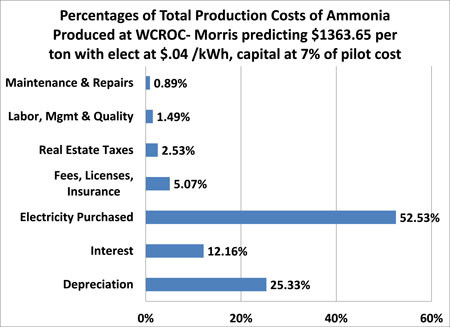

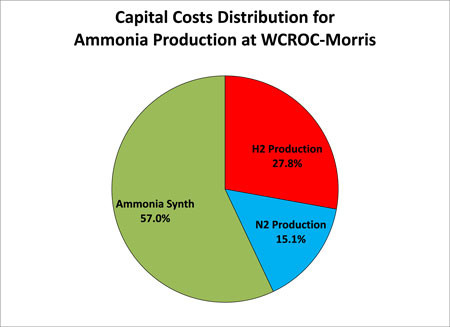

At the WCROC, research on producing and utilizing ammonia continues. Currently, two ammonia projects funded by the Minnesota Environmental and Natural Resource Trust Fund (ENRTF) are underway. The first project is a collaboration with many researchers across the University looking at developing technology, evaluating economics, and looking at policy. Economic results from data collected at the WCROC pilot plant are shown in Figures 3 through 6.

The second project funded by ENRTF uses ammonia from the WCROC pilot plant to displace diesel fuel in tractors. The technology which allows this conversion is being tested within the U of MN Department of Mechanical Engineering. The next step is to convert a WCROC tractor to run on ammonia. Field testing of this technology will begin this summer at the WCROC. In a third project, the renewable energy team was part of a successful grant application to the US DOE REFUEL program in collaboration with the Department of Chemical Engineering, the National Renewable Energy Lab (Golden, CO), and Proton On-site (Wallingford, CT) which is a leading manufacturer of electrolyzers. The objective of the project is to further develop a proprietary absorbent enhanced ammonia-production technology, scale up the technology, and test at the WCROC pilot plant beginning in the fall of 2018.

A possible next step is to study the possibility of using ammonia as fuel within a grain dryer. The Renewable Energy Program has a strategic plan to reduce fossil energy consumption in production agriculture. To accomplish this goal, we are combining renewable energy generation and energy efficiency to better utilize energy on the farm. Grain drying is a major consumer of energy but is not one that matches well with current renewable energy technologies since high amounts of energy are required in a short duration of time. One possible answer may be in the form of ammonia. The concept would allow for the use of ammonia seasonally as needed such as for fertilizer, transportation fuel, electrical energy generation, and then combusted in a grain dryer. We are in the process of evaluating the concept and discussing potential collaborations within the University to submit grant proposals.