By - Lara B. Moody

Editors - Benjamin C. Smith Brett C. Ramirez

Unless you are an accountant, record keeping is probably not your idea of fun. And, unlike your operation’s production records, you may not consider environmental records to be a necessity for your facility’s livelihood. However, kept properly, environmental records are beneficial to your facility, and in many cases, they are a requirement. As discussed here, environmental record keeping refers to items related to manure and nutrient management at and around the production facility. Environmental record keeping is a necessity for regulator-required nutrient and manure management plans (NMP or MMP) or for USDA’s Comprehensive Nutrient Management Plans (CNMP). In this fact sheet we will discuss how keeping environmental records can benefit your facility, what records should be kept, and how you can incorporate the records into the overall management of your facility.

Objectives

As a facility operator, knowing what records to maintain and understanding the benefits of environmental record keeping can help you incorporate record keeping as a best management practice. The objectives of this fact sheet are to:

• Explain why good environmental record keeping is important,

• Describe how environmental records can benefit facility management,

• Identify which environmental records should be kept, and

• Provide details for available record keeping templates.

In this fact sheet we will discuss how keeping environmental records can benefit your facility, what records should be kept, and how you can incorporate the records into the overall management of your facility.

Why Keep Environmental Records?

An obvious answer to this question is to satisfy record keeping requirements imposed by regulatory authorities or to meet the requirements of a CNMP. However, there are other considerations. The major benefits of environmental record keeping are accurate crediting of manure nutrients applied to cropland and improved management of manure storage areas for protection against accidental discharges. Even if you are not required by a regulatory authority to keep records, good environmental records can provide protection in the event of an extreme weather event or accident and can aid in verifying that your facility meets its planned best management practices.

How can Environmental Records Benefit my Operation

From a requirement stand point, either from a regulatory/permitting basis or to maintain contractual responsibilities to USDA-NRCS for received funds, record keeping is an obligation and is the primary way you prove you are properly implementing best management practices and that your operation is not adversely impacting the environment [1]. There are specific records which must be kept to document that you have met the requirements of your permit and/or that you are correctly implementing your CNMP. If you do not have any official obligations to provide environmental records, they can still provide you a benefit and protection. Public pressures and stricter enforcement of water quality regulations are putting animal agriculture under increased scrutiny. Record keeping and regular monitoring of structures and other critical areas is a good defense against accidental discharges [1] and public complaints.

Accurate crediting of manure nutrients applied to your cropland is a major benefit of environmental record keeping. Between 2002 and 2007, fertilizer prices doubled, and it has been estimated that the value of nitrogen in swine manure has increased from $11 per 1000 gallons in 2002 to $25 per 1000 gallons in 2007 [2]. Concise records documenting crop yields, soil tests, and manure nutrient application rates will allow you to take full advantage of the organic fertilizers available to you from your facility and allow you to reduce inorganic fertilizer inputs.

Regular monitoring of manure slurry storage structures and other critical areas will help protect against deterioration of the structure. Consistent recording of slurry levels in uncovered storages can provide documentation to regulators in the event of accidental discharges from extreme rainfall events. Recording of levels can also aid in management of the slurry (by providing an estimate of the volume available for land application and the time required to properly apply the slurry) and monitoring of water usage (a sharp increase in volume may indicate a waterline leak in the production building).

What Environmental Records should I keep?

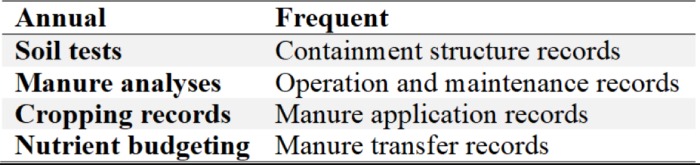

Environmental records should be kept for a minimum of five years. The extent of documentation required is dependent on whether or not the records are being kept to meet a requirement. In general, documentation to meet regulatory or NRCS-CNMP requirements can be classified as either “Annual” or “Frequent” records. A general list of record types are listed and described below. Even if you are not keeping records to meet such a requirement, the same documentation will still be useful to achieve the previously discussed benefits.

Table 1. Types of Environmental Records

Annual Records – Soil Tests

Soil tests should be collected every one to five years depending upon your state’s regulatory requirements. Many states now require one composite soil sample per 10 acres while other states have different requirements. At a minimum, the soil should be analyzed for pH, phosphorus, and potassium. The testing date, sample locations, and results should be recorded.

Annual Records- Manure Analyses

Under the best circumstances, samples should be collected and analyzed from each manure slurry storage area prior to the land application event. This allows the most accurate calculation of a nutrient based land application rate. Optimally, the storage area should be agitated prior to sample collection. Alternatively, the sample can be collected during removal and land application for future use while application rates are based on previous manure analyses. Final nutrient application rates would then be calculated using the results of the current manure analyses and amount of manure applied. Manure samples should be analyzed for nitrogen, phosphorus, and potassium.

Annual Records – Cropping System

In conjunction with soil tests, cropping records documentation allow the calculation of the required amounts of manure nutrients for a given crop. They will help a producer realize the savings as a result of reductions in inorganic fertilizer application. Cropping records should include planting and harvest dates, crop yields, and commercial fertilizer applications. Annual Records – Nutrient Budgeting. Performing an annual nutrient budget on your cropping system and available manure nutrients is essential. Nutrient budgets show that you are implementing the operation’s nutrient management plan. They also show system inputs and removal based on manure analyses, crop yields, and application rates.

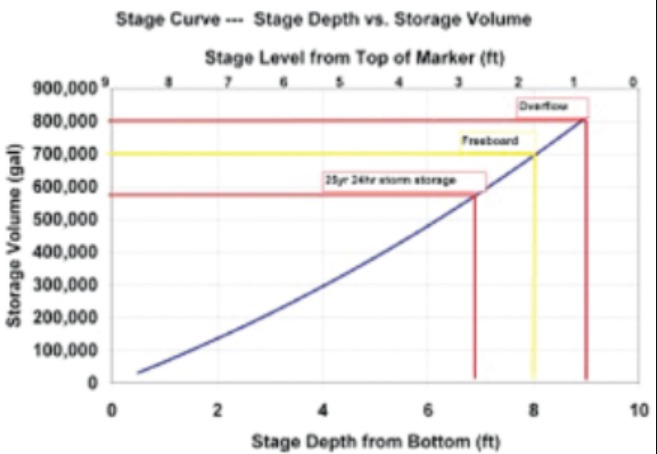

Figure 1. Stage Curve- Stage Depth vs. Storage Volume

Frequent Records- Containment Structure

Depth recordings in a containment structure are easiest to make if a stage marker is installed where it can be easily seen and read. Weekly recording of storage levels is adequate (unless otherwise required by regulations) for documentation. The date of emptying and the level before and after emptying should be recorded. The volume removed from the system can be used as an accuracy check against the measured application rate. A stage curve can be developed for your containment structure, similar to the one shown below, to allow determination of the approximate volume of slurry available for application based on stage marker depth, and it allows you to check the accuracy of your application rate based on the depth before and after slurry removal. For example, based on the chart below prepared for a specific holding pond, if you have 6 ft of slurry in the containment structure, a total of approximately 500,000 gallons is available for application. But if a depth of 1.5 ft of manure remains after removal, you have applied approximately 400,000 gallons (500,000 gal minus100, 000 gallons).

Frequent Records- Operation and Maintenance

These records help document upkeep of critical areas around your facility. They may include anything from inspections of storage impoundments and tanks to inspection of gutters to prevent clean water from entering manure storages. Notes concerning records of actions taken to correct deficiencies should be included in your documentation.

Frequent Records- Manure Application

These records should be maintained for each application event. They are a key factor in your facility’s nutrient budget. Documentation should include; the source of the manure (some facilities maintain multiple containment structures), application date, identification of the land areas that received the manure, application rate, weather and soil conditions during application, application method, and records of application equipment calibration.

Frequent Records- Manure Transfer

If applicable, document the amount of manure transported away from the operation (i.e. manure that is sold or given away). Because this practice is often the result of insufficient land availability at the production facility, such records provide documentation of adequate environmental management. Generally, you are not required to document how the manure is handled at the off site location once you no longer have ownership of it. However, in some states, a P-Index rating and RUSLE 2 score may be required for any fields receiving the manure.

Click here to see more...